Transform Your Space with Wood Flooring Plastic Panel Solutions

In today’s world, the choice of flooring and wall paneling can significantly influence the aesthetics and functionality of a space. Among the various options available, wood flooring and plastic panel solutions have emerged as popular choices due to their versatility, durability, and aesthetic appeal. The production processes involved in creating these materials play a crucial role in their quality, performance, and environmental impact. This article explores the manufacturing techniques behind wood flooring and plastic panels, highlighting how they can transform your space.

Wood flooring has long been favored for its natural beauty and warmth. The production of wood flooring typically begins with the selection of high-quality timber. Different species of wood, such as oak, maple, and cherry, each offer unique grain patterns and colors that can enhance any interior design. The selected logs are then debarked and cut into planks of varying thicknesses. This initial phase is critical as it determines the overall character and durability of the flooring.

Once the planks are cut, they undergo a drying process to reduce moisture content. This step is vital to prevent warping and cracking once the flooring is installed. The drying process can be achieved through air drying or kiln drying, with kiln drying being the more common method due to its efficiency and ability to control moisture levels precisely. After drying, the planks are planed to achieve uniform thickness and smooth surfaces, making them ready for finishing.

The finishing process involves applying protective coatings that enhance the wood’s natural beauty while providing resistance to scratches and stains. This can include oil-based or water-based finishes, each offering different levels of durability and sheen. The final product is then cut into specific sizes and packaged for distribution. The craftsmanship involved in producing wood flooring not only ensures a beautiful end product but also promotes sustainability when sourced from responsibly managed forests.

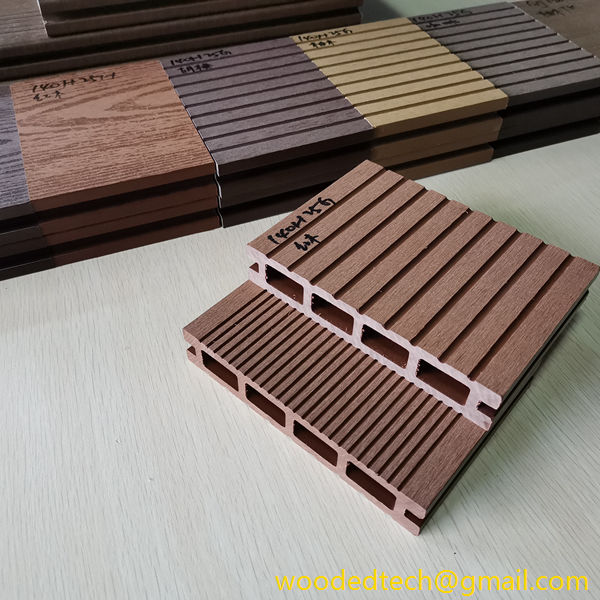

On the other hand, plastic panels have gained popularity due to their practicality and ease of maintenance. The production of plastic panels typically begins with the selection of raw materials, such as polyvinyl chloride or polypropylene. These materials are chosen for their durability, resistance to moisture, and ease of cleaning. The manufacturing process begins with melting the plastic pellets and extruding them into sheets of various thicknesses and sizes.

Once the plastic sheets are formed, they can be treated with various additives to enhance their properties. For example, UV stabilizers can be added to prevent discoloration from sunlight, while anti-microbial agents can be incorporated to inhibit the growth of mold and bacteria. After these treatments, the panels can be printed with designs that mimic the appearance of wood, stone, or other materials, providing an aesthetic appeal without the maintenance associated with natural materials.

The flexibility of plastic panels allows for various applications, from residential interiors to commercial spaces. They can be easily cut and shaped to fit any design requirement, making them an ideal choice for custom projects. Additionally, their lightweight nature simplifies the installation process, reducing labor costs and time.

When considering the environmental impact of both wood flooring and plastic panels, it is essential to acknowledge the strides made in sustainable production practices. Many manufacturers of wood flooring are committed to sourcing timber from certified sustainable forests, ensuring that their products do not contribute to deforestation. Additionally, advancements in recycling technologies have led to the development of eco-friendly plastic panels made from recycled materials, further reducing their environmental footprint.

In conclusion, wood flooring and plastic panel solutions offer unique advantages that can transform any space. The meticulous production processes involved in creating these materials ensure quality and longevity, making them suitable for various applications. Whether you prefer the timeless elegance of wood or the practicality of plastic, both options can enhance your interior design while contributing to sustainability. By choosing the right flooring and wall paneling, you can create a beautiful and functional environment that reflects your personal style and values.