WPC Fluted Panel Size Guide: A Comprehensive Overview from a Material Performance Perspective

Wood Plastic Composites (WPC) have become increasingly popular in various construction and design applications due to their unique combination of aesthetics, durability, and environmental benefits. One of the specific formats of WPC that has garnered attention is the fluted panel. This guide will delve into the size specifications of WPC fluted panels, while also highlighting their material performance characteristics that make them an excellent choice for both indoor and outdoor uses.

Understanding WPC Fluted Panels

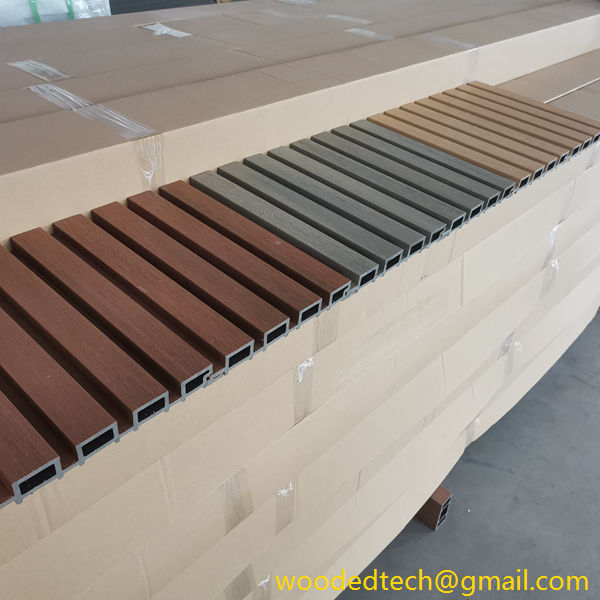

WPC fluted panels are engineered materials that combine wood fibers, thermoplastics, and additives to create a composite product. The fluted design refers to the vertical grooves or channels that run along the panel’s surface, providing not just a decorative effect but also enhancing structural integrity. These panels are commonly used for wall coverings, ceilings, and even furniture applications.

Size Specifications

WPC fluted panels typically come in various sizes to cater to different design needs. The most common dimensions include:

Thickness: Ranges from 6mm to 20mm. Thicker panels offer greater structural support and durability, making them suitable for high-traffic areas.

Width: Standard widths are usually 120mm to 300mm. Wider panels can create a more seamless appearance while reducing the number of joints required, thus minimizing potential weak points.

Length: Typically available in lengths from 2400mm to 6000mm. Longer panels reduce installation time and provide fewer seams, which can be beneficial in terms of aesthetics and performance.

These size options allow architects and designers to choose panels that best fit their specific project requirements without compromising on performance.

Material Performance Characteristics

When selecting WPC fluted panels, it is crucial to consider their material performance characteristics, as these will influence the longevity, appearance, and functionality of the final product.

1. Durability: WPC fluted panels are engineered to withstand various environmental conditions. They are resistant to moisture, reducing the risk of warping or swelling, which is often a concern with traditional wood materials. This characteristic makes them particularly suitable for outdoor applications, including landscaping and façade cladding.

2. UV Resistance: The exposure to sunlight can lead to fading and degradation in many materials. WPC panels are often treated with additives that enhance their UV resistance, ensuring that colors remain vibrant over time and reducing the need for regular maintenance.

3. Fire Resistance: Many WPC products are designed to meet specific fire safety standards. By incorporating flame-retardant additives, manufacturers can create panels that not only comply with building regulations but also provide peace of mind in terms of safety.

4. Impact Resistance: The combination of wood fibers and plastics gives WPC panels a level of impact resistance that is superior to traditional wood. This means that they can withstand accidental bumps and knocks, making them ideal for high-traffic areas or environments where durability is paramount.

5. Thermal Stability: WPC materials demonstrate lower thermal expansion compared to solid wood. This stability minimizes the risk of warping or cracking due to temperature fluctuations, making WPC fluted panels a reliable choice for various climates.

6. *Aesthetic Versatility: WPC fluted panels can be manufactured in a variety of finishes, colors, and textures, allowing for creative design possibilities. The fluted texture not only adds visual interest but also enhances the tactile experience for users.

Installation and Maintenance

The ease of installation is another important aspect of WPC fluted panels. The lightweight nature of the material allows for straightforward handling and cutting, reducing labor costs and time on-site. Additionally, maintenance is minimal; a simple cleaning with soap and water is often sufficient to keep the panels looking fresh.

Conclusion

WPC fluted panels represent a remarkable fusion of aesthetics and performance, making them an excellent choice for a wide range of applications. Understanding the various size specifications and material performance characteristics can help architects, designers, and builders make informed decisions that align with project goals. Whether for residential or commercial projects, WPC fluted panels not only enhance visual appeal but also promise longevity and reliability, proving to be a worthy investment for any construction endeavor.