Wood Plastic Composites, commonly known as WPC, have gained significant popularity in the construction and interior design industries due to their durability, aesthetic appeal, and environmental benefits. WPC wall panels are one of the most sought-after products in this category, offering a versatile solution for both residential and commercial applications. The production process of WPC wall panels involves several key steps, each contributing to the overall quality and performance of the final product.

The first stage in the production of WPC wall panels is material selection. WPC is typically made from a combination of wood fibers and thermoplastic resins. The wood fibers can be sourced from recycled wood products, sawdust, or wood shavings, which align with sustainability goals. The thermoplastic resins, often polypropylene or polyethylene, are selected for their durability and resistance to moisture and decay. This careful selection of raw materials is crucial as it influences the physical properties of the wall panels.

Once the materials are chosen, the next step is the compounding process. During this phase, the wood fibers and plastic resins are mixed together, often with additives that enhance the properties of the composite. These additives may include colorants, UV stabilizers, and anti-fungal agents. The compounding process is typically conducted using twin-screw extruders, which ensure thorough mixing and homogeneity of the material. This step is vital as it determines the consistency and overall quality of the WPC wall panels.

Following compounding, the material is subjected to extrusion. In this process, the compounded WPC mixture is fed into an extruder where it is heated and forced through a die to create continuous panels of the desired shape and size. The extrusion process allows for the production of panels with varying thicknesses and profiles, catering to different design preferences and installation requirements. The temperature and pressure settings during extrusion are carefully controlled to ensure optimal flow and to prevent degradation of the materials.

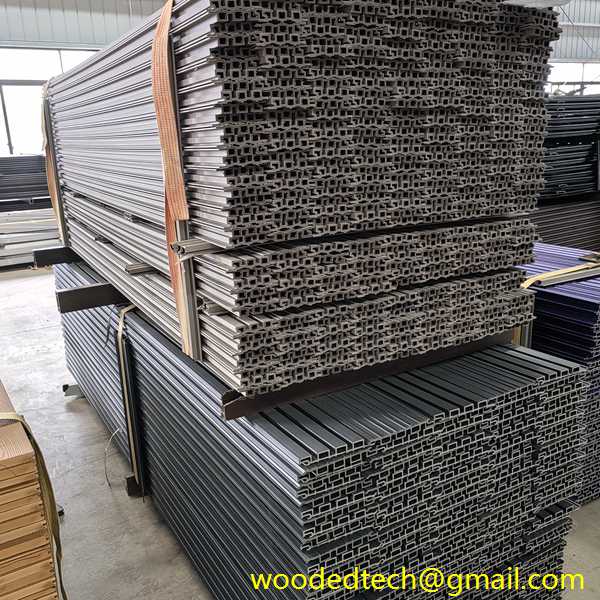

After extrusion, the panels are cooled and cut to size. This cooling process is essential as it solidifies the material and enhances its structural integrity. The cut panels are then subjected to quality control inspections to check for any defects or inconsistencies. This stage is crucial to ensure that only high-quality products are delivered to customers.

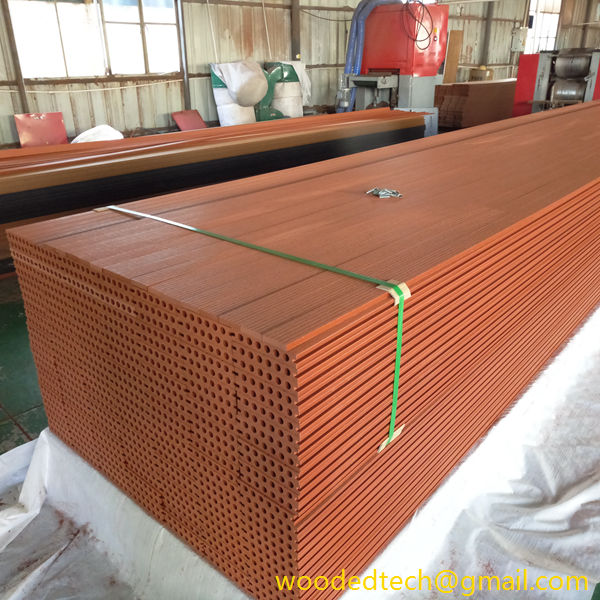

Finishing touches are added to the WPC wall panels to enhance their aesthetic appeal and functionality. This can include surface treatments such as embossing, laminating, or applying a protective coating. These finishing processes not only improve the visual aspects of the panels but also increase their resistance to wear, fading, and moisture penetration. The choice of finish can vary based on the intended application, whether it be for interior decoration or exterior cladding.

The production of WPC wall panels also incorporates eco-friendly practices. Many manufacturers strive to minimize waste during the manufacturing process. For instance, any excess material generated during cutting or shaping is often recycled back into the production line, thereby reducing the overall environmental impact. Additionally, the use of recycled wood fibers not only lessens the demand for virgin wood but also promotes sustainable forest management.

In terms of applications, WPC wall panels are incredibly versatile. They can be used in a variety of settings, including residential homes, commercial buildings, and outdoor spaces. Their resistance to moisture and insects makes them ideal for areas prone to humidity, such as bathrooms and kitchens. Moreover, WPC panels can be designed to mimic the appearance of natural wood, providing an attractive alternative to traditional wood products without the associated maintenance concerns.

In conclusion, the production of WPC wall panels involves a comprehensive process that begins with material selection and ends with finishing touches that enhance their appeal and functionality. The careful combination of wood fibers and plastic resins results in a durable, eco-friendly product that meets the demands of modern design and construction. With their numerous benefits, WPC wall panels have become a preferred choice for architects, builders, and homeowners alike, leading to a growing list of products available for selection in the market. As the industry continues to evolve, we can expect further innovations in WPC technology, expanding the possibilities for these versatile wall panel products.