Verkennen van weerbestendige wandpanelen voor buiten voor bescherming in alle weersomstandigheden

When it comes to designing and constructing buildings, one of the primary considerations is the protection of structures from various weather conditions. Weatherproof outdoor wall panels have become a popular solution for ensuring all-weather protection while enhancing the aesthetic appeal of buildings. These panels are not only engineered to endure the elements but also designed with a focus on material production processes that facilitate durability, insulation, and ease of installation.

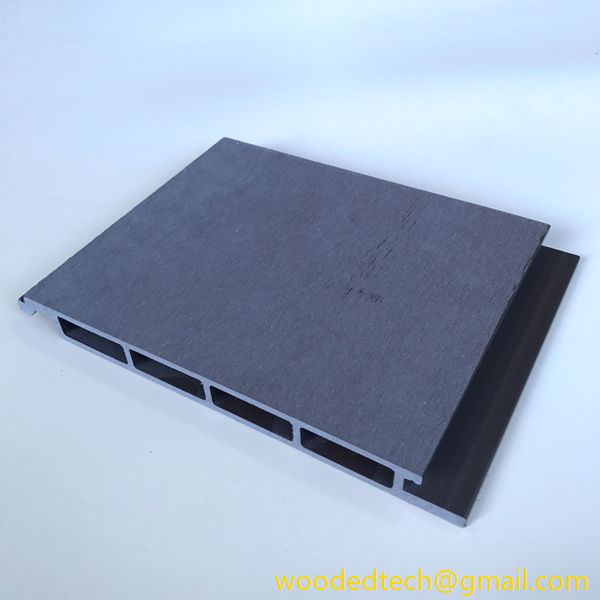

The production of weatherproof outdoor wall panels begins with the selection of materials. Commonly used materials include vinyl, fiber cement, wood composites, and metal. Each material has unique properties that contribute to the overall performance of the panels. For instance, vinyl panels are known for their resistance to moisture and decay, making them an ideal choice for humid environments. On the other hand, fiber cement offers superior strength and fire resistance, making it suitable for areas prone to extreme weather conditions.

Once the materials are selected, the manufacturing process plays a crucial role in determining the quality and longevity of the panels. For vinyl panels, the extrusion process is commonly used, where raw plastic materials are heated and forced through a mold to create the desired shape. This process allows for the creation of panels that are uniform in thickness and appearance, ensuring consistent quality throughout production. Additionally, additives can be included in the formulation to enhance properties such as UV resistance and impact strength, further improving the panels’ performance in outdoor settings.

For fiber cement panels, the production process involves mixing cement with cellulose fibers and other additives to create a composite material that is both lightweight and strong. The mixture is then formed into sheets and cured under controlled conditions. This curing process is essential as it allows the panels to achieve their final strength and durability. The versatility of fiber cement panels makes them suitable for a range of architectural styles, and their weather-resistant properties make them a popular choice among builders and homeowners alike.

Another important aspect of the production process is surface treatment. Weatherproof outdoor wall panels often undergo various finishing techniques to enhance their performance and appearance. For example, panels may be coated with weather-resistant finishes that provide an additional layer of protection against moisture and UV rays. These coatings not only improve the longevity of the panels but also allow for a wide range of color options, enabling designers to achieve specific aesthetic goals.

In addition to material selection and manufacturing techniques, the installation process of weatherproof outdoor wall panels is designed to maximize their protective capabilities. Proper installation is critical to ensuring that the panels perform as intended. This includes following manufacturer guidelines regarding spacing, fastening, and sealing. For instance, the use of appropriate sealants and flashing can prevent water infiltration, which is a common cause of damage in exterior wall systems. Furthermore, the design of the panel system often incorporates drainage features that allow any moisture that does penetrate to escape, reducing the risk of mold and deterioration.

Moreover, the sustainability of weatherproof outdoor wall panels has become an increasingly important consideration in their production and application. Many manufacturers are exploring eco-friendly materials and processes that minimize environmental impact. For instance, some fiber cement panels are produced using recycled materials, while vinyl panels can be manufactured from post-consumer recycled content. Additionally, the longevity of these panels contributes to sustainability, as longer-lasting materials reduce the need for frequent replacements and repairs.

In conclusion, weatherproof outdoor wall panels represent a significant advancement in building materials, providing reliable protection against the elements while offering aesthetic versatility. The production process, from material selection to manufacturing techniques and installation practices, plays a vital role in ensuring the performance and durability of these panels. As the construction industry evolves, ongoing innovations in materials and processes will likely lead to even more effective solutions for all-weather protection, making weatherproof outdoor wall panels an essential component of modern architecture. Whether for residential or commercial applications, these panels stand out as a testament to the balance between functionality, aesthetics, and sustainability in building design.